Non Stop Scaffolding

The advantage of using Non-Stop Heavy-Duty Scaffolding™ is that it saves you money by increasing your production. This system involves a single platform that moves up and down vertical towers. Instead of spending labor dollars setting up additional frames and planking the next level up, the scaffolding is simply raised (or lowered) using winches, allowing you to use 1/3 fewer planks. This type of scaffolding is also called crank-up scaffolding and elevated-platform scaffolding.

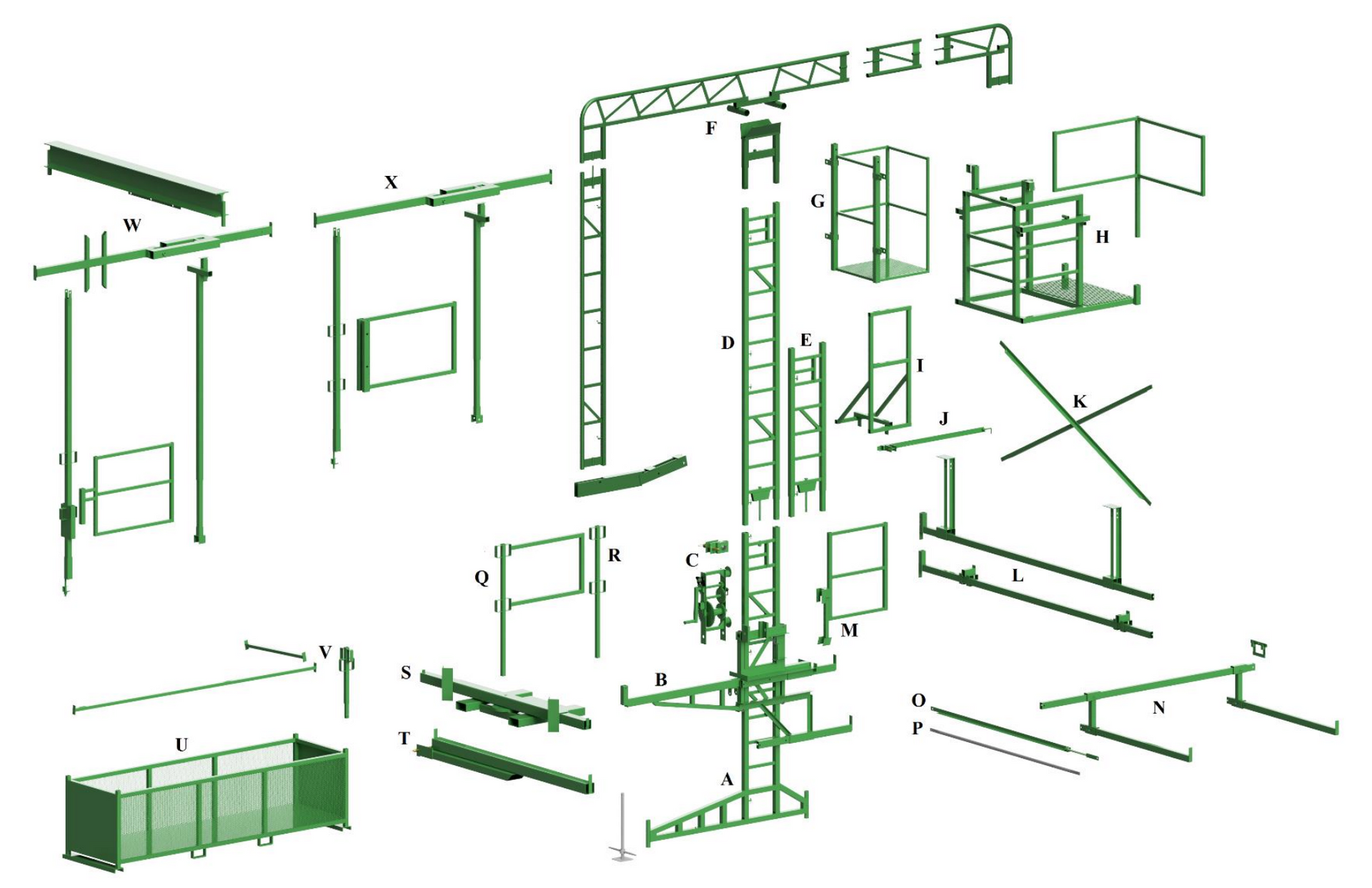

A. 9’ Base Tower 91 lbs.

B. Elevating Carriage 127 lbs.

C. Winch and Pulley Assembly 74 lbs.

D. 9’ Tower Extension 70 lbs.

E. 4’-6” Tower Extension 31 lbs.

F. Winter Enclosure Assembly 200 lbs.

G. Rest Platform 52 lbs.

H. Access Landing 171 lbs.

I. Barricade Guardrail 31 lbs.

J. Wall Tie-in Bracket 10 lbs.

K. X-Brace 17 lbs.

L. Inside Corner Bracket Assembly 86 lbs.

M. Masons’ End Guardrail 25 lbs.

N. Pilaster Bracket Assembly 52 lbs.

O. Adjustable Straight Brace 13 lbs.

P. Straight Brace 13 lbs.

Q. Laborers’ End Guardrail 25 lbs.

R. Guardrail Post 13 lbs.

S. Swivel Forklift Bar 225 lbs.

T. Side-Stab Forklift Bar 85 lbs.

U. Parts Basket 315 lbs.

V. Parts Basket Guardrail Kit 59 lbs.

W. Hoist Assembly 231 lbs.

X. Overhead Protection Assembly 126 lbs.

CONTACT DETAILS

Phone: 347-719-0228

Email: a.s@erectormasters.com

Address: 1119 Webster Ave, Bronx, NY 10453

Financing Available

BUSINESS HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed

WE ARE MBE CERTIFIED BY:

MBE (NYC SBS)

NYC SCA SCAFFOLD

DASNY MBE

NYC DEP

NJ&NY Port AUTHORITY

OUR LOCATION